|

|

121 |

Remove the front wheel.

Loosen the axle clamping bolts on both sides of the forks. Unscrew the axle and remove the wheel. |

| 122 | Remove the forks complete with the lower fork clamp. Remove the top round nut that secures the lower fork clamp and the steer tube bearings. Use BMW No. 31 6 521 or a soft aluminum drift and a hammer.

Check the steering bearings and replace if necessary. |

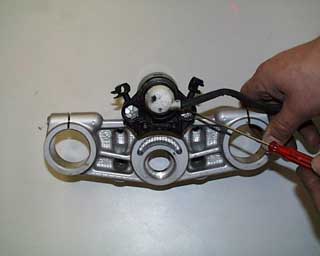

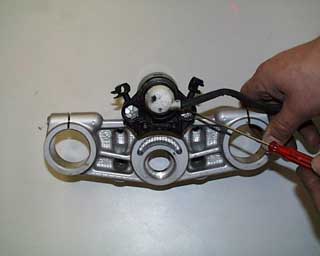

| 123 | The parts for the front end replacement are as follows:

(1) Handle bars risers

(2) Lower bar clamps

(3) Upper bar clamps

(4) New caliper mount

(5) Sensor cover

(6) Steering stops

(7) Sensor mount |

| 124 | Install the new lower fork clamp into the head tube with the bearings and secure with the original round nut. The adjustment of the nut comes after the installation of the complete front end. The two steering stops are bolted to the clamp with two M8x20 bolts and washers. Secure the stops with Loctite 243. |

| 125 | Remove the ignition assembly. The two bolts that secure the Ignition switch will need to be drilled out to remove them. TIP: If no drill press is available, the clamp can be placed onto the fork tubes and held for drilling.

NOTE: There are two versions of the Ignition assembly. If your switch is the long (130mm) completely black version (without the white bottom) you will need to modify the assembly. Remove the lower half of the switch from the lock cylinder by removing the two Phillips head screws. Remove the cable tie that secures the wires to the bottom of the black plastic cover. Very carefully cut the bottom off of the housing to a total length of 45mm. Be extra cautious near the wires. You will need to cut halfway through the original hole in order to free the wires. Once you have freed the wires you can remove the switch and finish modifying the cover to the proper length. Drill two small holes in the cover approx 10mm up from the bottom on the left-hand side (left-hand side as if you were facing forward on the bike) that will be used to run a cable tie through to secure the wires. Place the switch back into the shortened cover, secure the wires to the side of the cover and seal the bottom of the now exposed switch with an insulating potting compound. Reinstall the switch on the lock cylinder using the original screws. |

| 125a |

| 126 | The ignition lock/switch assembly (modified or not) can now be installed onto the new mounting bracket with two M8x25 bolts (6mm hex) and the original washers. Secure the bolts with Loctite 243 |

| 127 | 127-128 The upper fork clamp is installed on the steer tube and the top locknut installed. The top nut is not tightened until the two clamps are aligned, or the forks have been installed which will insure the alignment of the two clamps. The ignition switch assembly is installed onto the upper clamp with two M6x14 (5mm hex) bolts and secured using Loctite 243. The handlebar mounts are installed onto the fork clamp with two M10x70 bolts from above with washers and locknuts below. Do not tighten these yet as the bars will be needed to insure that the mounts are properly aligned. The pinch bolts can now be installed into the fork clamps. 6 of the bolts will be M8x35, and two are M8x40. The two longer bolts are installed where shown, the uppermost and lower most holes in the left side. Under these two bolts install two each of the turned down M8 washers and a loop clamp (12mm) that will be used to guide the brake line and the sensor wire. The washers are used as spacers to space the loop clamps out away from the fork clamp. |

| 128 |

| 129 | The forks can now be installed into the fork clamps. The brake caliper sits on the left hand side. Tighten the pinch bolts of the lower clamp to 15ft/lbs. The round nut of the steer tube can now be tightened to 18ft/lbs, with the BMW tool No. 31 6 521. Tighten the center countering tube (2), and finally the top locknut (1) to 48f/lbs. The forks have three grooves machined into the top of the fork tube to be used as a guide, the position at this point is not critical, as long as both fork tubes are set to the same height. Tighten the remaining upper fork pinch bolts to 15ft/lbs.

NOTE: If no special tool is available to tighten the round nut, tighten by hand so there is no axial play in the forks with the complete front end assembled (including the front wheel) and the forks can turn with very little resistance. |

| 130 | Install the handlebars.

Place the MAGURA X-line bars into the mounts and place the top mount halves in place and start the four M8x35 bolts (6mm hex) Once the mounts are in alignment tighten the two M10 mounting bolts from below the fork clamp to 30ft/lbs. If the bolts try and turn while you are tightening them remove the bars and hold the bolts from the top while they are being tightened. Now the handlebars can be centered using the etched markings on the bars and the clamping bolts can be tightened to 16ft/lbs. |

| 131 | Install the fork slider covers. Into the three holes at the bottom of the covers place the three small bushings, then install the fork slider covers with the six M6x12 bolts (4mm hex) and six large washers. Place the brake line support clamp onto the left side cover. |

| 132 | Remove the brake pads from the caliper, and take the caliper off of the original mounting plate. Unscrew the pin from the original caliper bracket. (It is secured with high strength Loctite) Also remove the small metal clip and the rubber boot from the caliper bracket. |

| 133 | The parts we removed from the brake caliper mounting bracket are once again installed onto the new mounting bracket. The pin is installed using Loctite 270. The rubber boot and the metal clip are also installed. The pins and the metal clip can be lubed slightly with a copper anti-seize paste. |

| 134 | Reassemble the brake caliper.

Place the caliper onto the new bracket, reinstall the brake pads, along with the pin and safety clip. Now the complete brake caliper is installed onto the left fork with two M8x35 bolts and washers. Tighten the bolts to 15-18ft/lbs. Be careful to keep the brake pads clean and free of any grease while assembling and installing the caliper. |

| 135 | The wheel speed sensor is installed into the mounting bracket as shown in the photo. |

| 136 | The front brake disc is installed onto the new wheel the same as in the rear. (torque 7ft/lbs, and Loctite 243) The sensor magnet in the 43mm long bolt is installed into the front wheel hub and adjusted using the two nuts (8mm wrench). Adjust the magnet so that the clearance between the magnet and the sensor does not exceed 1mm. The sensor cover installed over the sensor with two M4x8 bolts (2.5mm hex). The sensor assembly is secured in place using the front axle. The front axle is installed from the right hand side and secured with the hub nut on the left. The hub nut is tightened to 12-15ft/lbs. Finally the four pinch bolts are tightened to 15ft/lbs to lock the axle in place. |

| 137 | Assemble the oil cooler.

The cooler is installed onto the mount using the short spacer (1) (18.5 mm) with an M6x40mm bolt (5mm hex) two washers and a locknut. The other side (2) uses the longer (26.5mm) spacer and an M6x45 bolt with washers and locknut. On the right hand side, under the shorter bolt (1) the mounting bracket for the horn is installed. |

| 138 | Assemble the double headlamp assembly.

Place the two rubber bushings (1) and the metal spacers into the headlamp unit. The fork piece of the adjusting rod is fastened to the adjusting screw with an M6x20 button head (4mm hex). The rod is now attached to the headlamp plate from the front with a M6x16 button head (4mm hex) |

| 139 | Place the compression spring onto the adjusting rod, and place the rod through the faring mount. After the rod is positioned through the hole in the mount, push on the headlamps to compress the spring and screw on the knurled plastic nut. After the plastic nut a M5 locknut is installed as a safety. The double headlamp assembly is mounted to the faring mount at the top with two M6x35 button head bolts with washers and locknuts. |

| 140 | Place the fuel tank vent hose from the central tank along with the prepared oil line (from step 97) above the coolant tank and forward through the forks. |