41

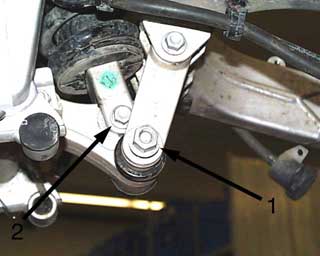

Remove the lower swing arm linkage bolt (1) so the shock bolt can be removed. Be careful with the two dust caps when removing the linkage bolt. Now remove the lower shock bolt. (2)

Place the shock reservoir through the frame where the original adjuster had been. Place the shock down through the frame and install the original upper shock bolt with the washers and locknut.

The swing arm linkage bolt can now be tightened to 53ft/lbs.

Disconnect the plug for the oil pressure switch.

Remove the original shock reservoir mounting bracket and the voltage regulator. Save the sheet metal nuts, spacers and the rubber bushings.

Remove the plug from the temperature sensor. Remove the two screws and pull outward on the clip that connects the two halves of the air cleaner housing together. Pull outward on the intake and then back to remove.

Take off the two nuts that secure the battery box. The battery box with nuts and washers will be reused.